Collision

Carrosserie Denis Inc Strengthens Its Market Position by Earning Official Certified Collision Center Status

Wheel restore: Transforming alloy wheel repair in Canada

The demand for alloy wheel repair is booming across Canada, driven by growing emphasis on cost-effective solutions, sustainability, and advanced technologies.

As more vehicle owners choose repairs over costly replacements, Wheel Restore, a global leader in alloy wheel repair automation, is equipping Canadian workshops with cutting-edge machines that enhance repair quality, optimize operational efficiency, and deliver exceptional return on investment.

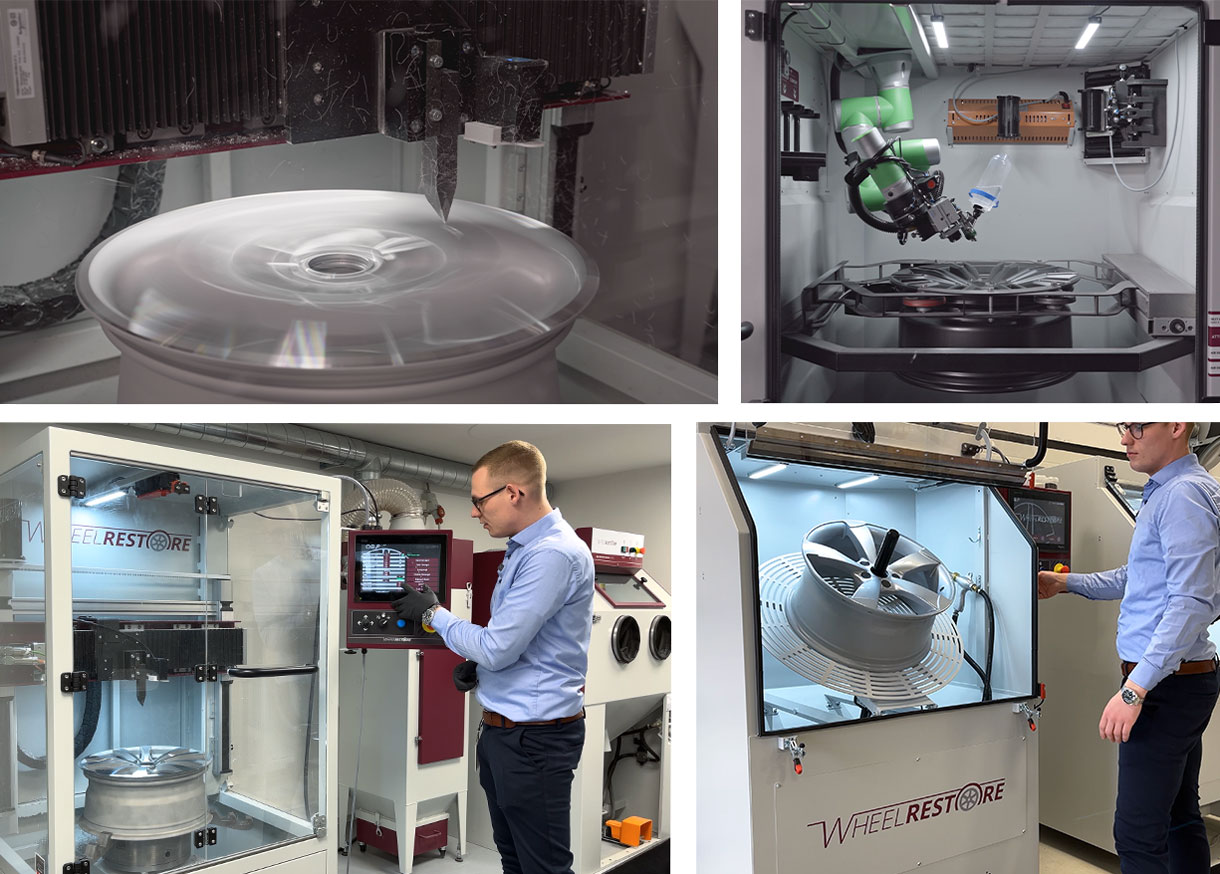

By offering a complete line of advanced equipment—including CNC diamond cutting, automated wheel painting, electrohydraulic straightening, sandblasting, and mobile solutions—Wheel Restore enables Canadian businesses to capitalize on the rapidly growing alloy wheel repair market.

Revolutionizing Wheel Repair with Precision and Efficiency

At the heart of the Wheel Restore lineup is the diamond-cut wheel repair machine, a fully automated high-precision lathe designed to restore alloy wheels to their original finish. This machine makes micro-millimeter adjustments while preserving structural integrity, ensuring each wheel is repaired in just 15 minutes—allowing Canadian workshops to provide top-tier service and quality to their customers.

A High-Yield Investment for Canadian Shops

Engineered to maximize profitability, the Diamond Cut machine offers an impressive return on investment, often paying for itself in a short time. With minimal material costs per repair and strong market demand, shops can generate significant revenue by adding alloy wheel restoration to their core services. Many Canadian workshops are seeing the benefits, from reduced overhead to higher customer satisfaction

Gérard Desloges, Éric Fortin, Yannick Desloges

Why Alloy Wheel Repair Is Booming in Canada?

High Return on Investment: Alloy wheel repair costs only a fraction of a full replacement, making it a profitable service for workshops and a money-saver for motorists.

Eco-friendly Alternative: Repairing instead of replacing reduces demand for new wheels, lowering raw material extraction and carbon emissions—aligned with Canada’s sustainable development goals.

Rising Market Demand: With over 33 million vehicles on Canadian roads, more owners are choosing repair as an economical, eco-friendly solution—driving the need for high-quality automated repair solutions.

Enhanced Wheel Finishing with the World’s First Automated Painting System

The wheel painting robot, a patented automated system, complements the CNC machine and eliminates inconsistencies while reducing paint use by up to 50%. Whether using a spray gun or aerosol, this system ensures a flawless, workshop-quality finish while minimizing overspray and waste.

By integrating diamond cutting and automated painting, Canadian repair shops can offer a complete alloy wheel restoration service with unmatched efficiency and quality.

Expanding Capabilities with Advanced Repair and Maintenance Equipment

Beyond diamond cutting and painting, Wheel Restore offers a full ecosystem of repair solutions to optimize shop operations in Canada:

Electrohydraulic Wheel Straightener: This system restores damaged and warped wheels to their original shape using precision hydraulic pressure and heating technology. Capable of repairing aluminum and steel wheels up to 30 inches, it ensures perfect balancing before any further repair.

Sandblasting Booth with Filtration System: Proper surface preparation is essential for quality repair. The sandblasting booth effectively removes corrosion, dirt, and old coatings, while its integrated dust removal system keeps the shop clean and safe.

Universal Spare Wheel: Downtime is a major concern for Canadian customers. This temporary replacement wheel fits 98% of vehicles, keeping owners on the road during wheel repairs and boosting customer satisfaction.

Made in Denmark: Uncompromising Quality and Innovation

The Wheel Restore product line is manufactured in Denmark, combining premium materials with top-tier components. Our machines stand out for their compact, lightweight, and stylish design, hallmarks of Danish functionality and craftsmanship. Unlike many competitors, Wheel Restore products are built to maximize performance and space efficiency, making them ideal for any workshop environment.

In addition to their innovative design, the products feature ultra-intuitive, modern software that makes them exceptionally accessible. Whether for seasoned technicians or new hires, the user-friendly interface ensures quick training and smooth operation—minimizing downtime and increasing productivity. This level of accessibility empowers Canadian workshops to integrate our technology with ease.

L'Automobile Magazine

News

Business Directory

En

En  Fr

Fr