Business

Magna International Sees Opportunity in Chinese Expansion

Roger Allard revives the brand that bears his name

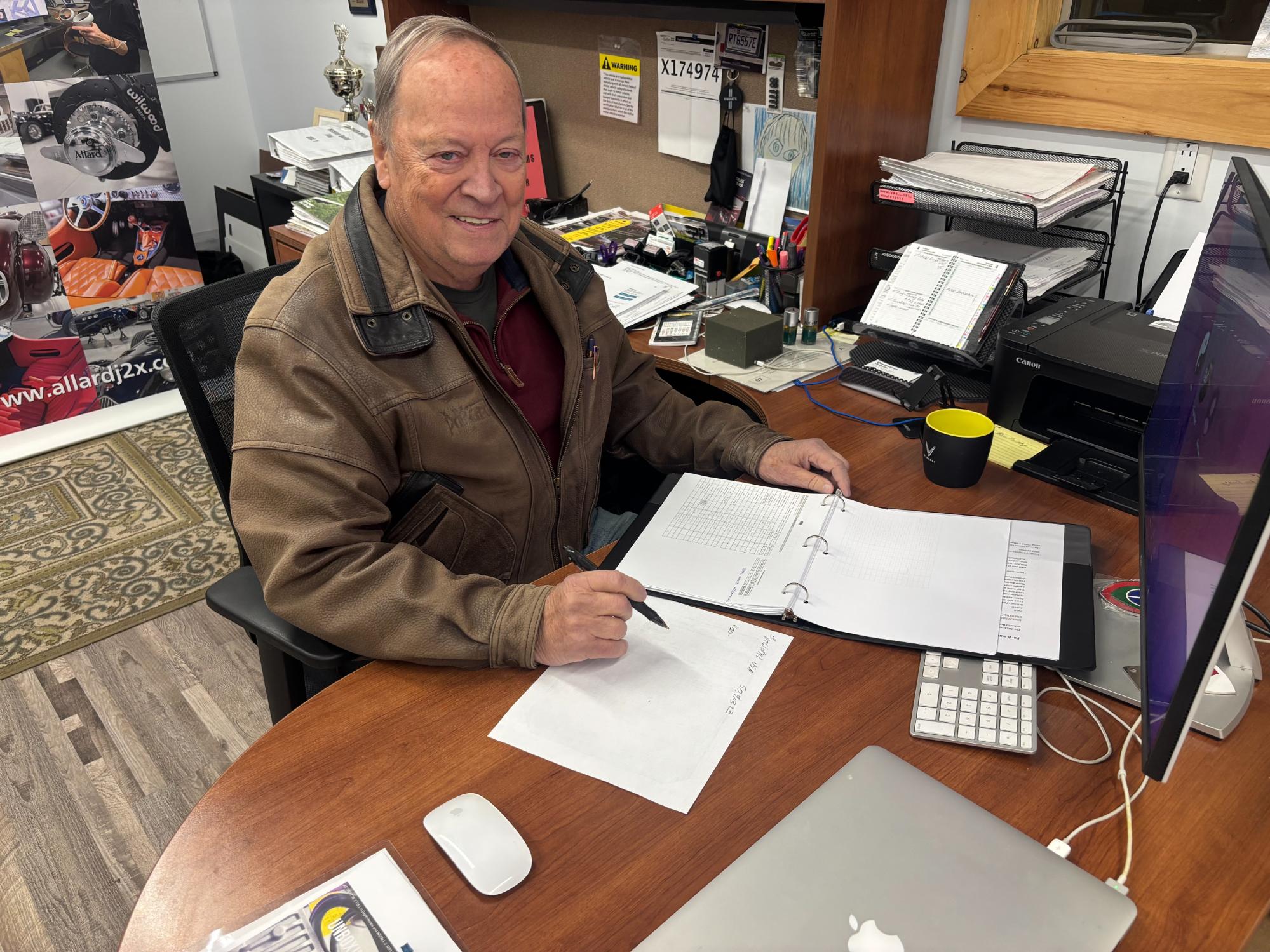

A few months ago, we published an article about one of Québec’s small automakers. At the time, it focused on Michel Pigeon, well known in the community for his Cobra and Ford GT-40 replicas. But Pigeon isn’t alone in this field. While he may be one of the most prolific builders in the province, we also have to mention Roger Allard. He doesn’t build at the same pace as Pigeon, but his vehicles are far more sophisticated — and more expensive!

The cars Roger Allard builds are also replicas — but of much older and much rarer vehicles than Pigeon’s. In fact, Roger Allard runs a small company in Laval that builds replicas of… Allards! And not just any models, but the J2X, originally produced from 1952 to 1954 by British automaker Sydney Allard.

Roger Allard, a Franco-Ontarian, wasn’t originally part of the automotive world. He was a communications consultant — a “problem solver,” as he likes to call himself. He first learned about the Allard brand in the 1990s, through magazines. He eventually saw his very first Allard at the famous Beaulieu Museum in England. It was love at first sight. He had to have one.

Roger then learned that an American in San Diego had been producing (poor) replicas. So he went all in — not just to buy a replica, but to acquire the entire company, including the fiberglass body molds. Seeing that everything needed to be redone, he turned to skilled individuals — talented Quebecers who knew how to do exceptional work. It’s no surprise that the name Terry Maxwell (a.k.a. Zeke — whose story also happens to appear in this issue) came up. Together, they assembled the first example.

Roger Allard is a perfectionist. He eventually created his first prototype, the Allard 001, which was quickly snapped up by a collector in Sedona, Arizona. Roger personally delivered the car, but on his way to the American Southwest, he made a detour to Santa Monica, California, where a dealer had arranged a visit with renowned collector and television personality Jay Leno. That first meeting is even available to watch on YouTube.

After a four-year adventure in California — where the market for exceptional cars is especially strong — Roger returned to Québec. For the past four years now, he’s once again been operating a small, ultra-specialized workshop in an industrial park in Laval. When we visited in early November, the company, Les Automobiles Allard (or more affectionately, Allard Motor Works), was working on vehicles number 027 and 028.

Of course, Roger always saw the U.S. market as his main outlet. However, recent policy changes under its president (Trump, though unnamed) somewhat dampened the enthusiasm of the entire collector car industry. Roger himself had a less-than-pleasant experience when trying to deliver a new vehicle across the border. Upon arriving at customs, officers demanded a rather hefty “tariff” to let the car through. Our entrepreneur decided to turn back and reassess his accounting.

But that was just a temporary setback. Roger Allard won’t be discouraged so easily. In fact, he’s already found buyers in New Zealand, China, Spain, Switzerland, and elsewhere. He’ll find a way forward — no doubt about it.

The Car

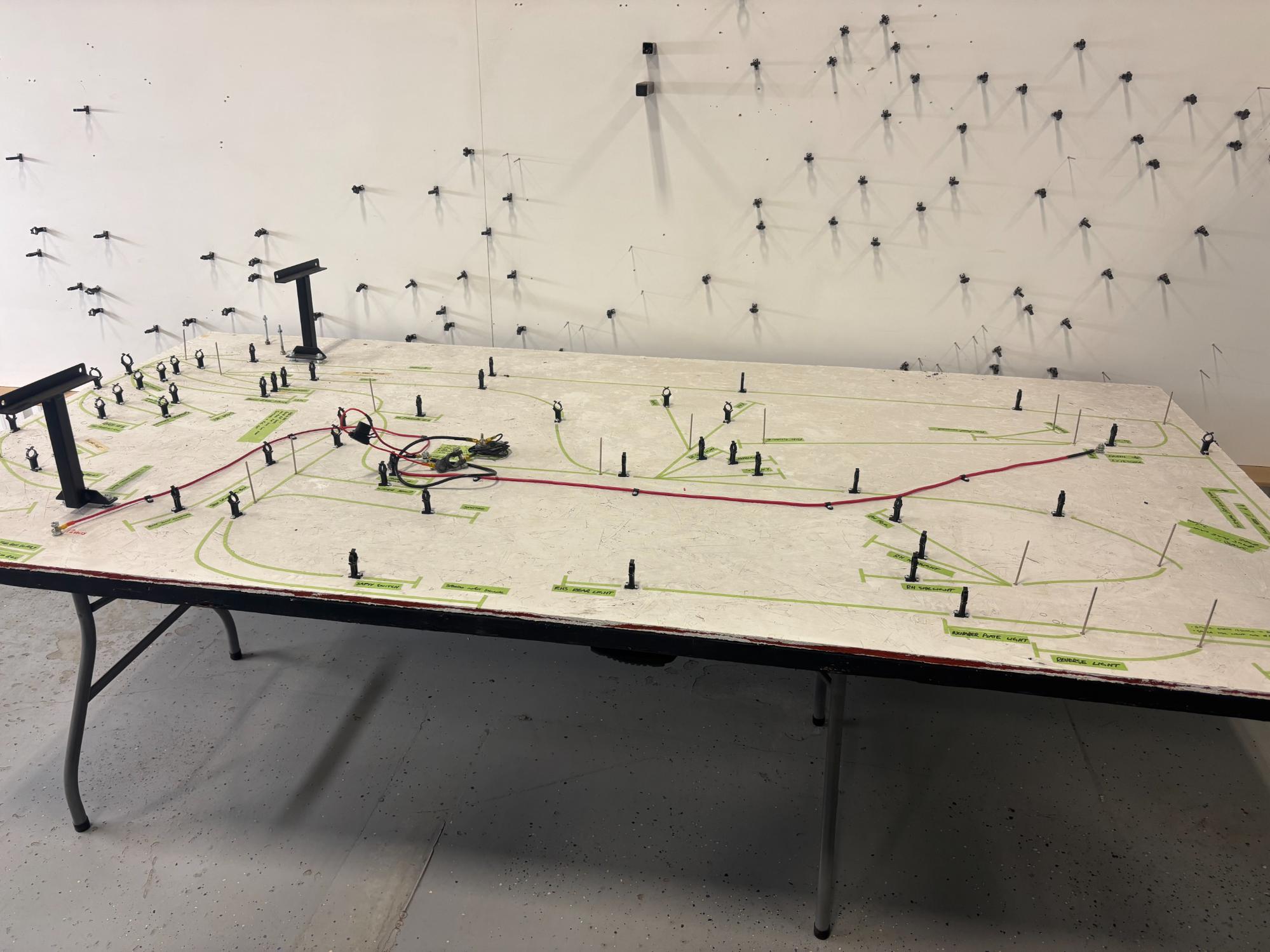

At Allard Motor Works in Laval, only one model is produced: the J2X roadster (though there’s something new in the works… but it’s still a secret!). The chassis is hand-built on-site, with a wheelbase that’s five inches longer than the original 1950s Allard models to make cabin access easier. Meanwhile, Allard’s lead technician, British native Greg Baker — formerly a mechanic for some Formula One teams — carefully oversees the assembly of the suspension and mechanical components.

Originally, the J2 models could be powered by Ford Flathead V8s, but when the J2X series launched in the 1950s, customers started receiving 331-cubic-inch Cadillac and Chrysler Hemi V8s. Roger Allard has kept this spirit alive by choosing modern Cadillac V8s, Chevrolet LT3 and e-Rod engines, as well as 5.7L and 6.1L Chrysler Hemis, paired with either a manual Tremec transmission or a GM automatic.

“What’s nice about the GM engines,” says Baker, “is that they can come with factory electronic connections, which makes integrating the electronics easier and helps with emissions compliance.”

It’s worth noting that the new Allards are fully compliant with strict modern emissions standards — including those set by the NHTSA (National Highway Traffic Safety Administration). Each vehicle comes with its own certified VIN number. Currently, Allards leave the factory equipped with Uniroyal tires.

Thanks to advances in computing, Allard Motor Works is now able to manufacture many parts in-house — components that previously had to be sourced from small, often unreliable suppliers that couldn’t always meet the brand’s high standards. Today, the company uses 3D printers and a CNC machine in its operations.

It’s also worth noting that Allard shares its space with another company it collaborates with — Felino — which will be featured in an upcoming issue.

The fiberglass or carbon fiber bodywork (depending on the customer’s choice) is now created using the molds purchased in California, which were carefully refined over time. Faithfully reproducing the original lines, these bodies have been slightly modernized — if only by the addition of a rear trunk that can fit two golf bags!

We had the privilege of seeing a mock-up of a removable roof prototype, which is expected to be offered a bit later. It’s worth noting that the front hood is made of metal — a component Roger Allard entrusts to a specialist who handcrafts each individual louver! The car’s paint is baked for a durable, high-end finish.

Special attention has been given to the interior, where the leather finish is simply impeccable. Even the (classic-style) gauges are custom-made for Allard, proudly displaying the brand’s name in the original typeface.

In one of the completed models awaiting delivery, Roger Allard showed us a few modern additions, such as a wireless phone charging pad — and one less modern but delightful touch: a storage case between the two seats for… an umbrella!

Now, the big question: how much does an Allard cost? For the moment, Roger Allard gave us a clear answer: $225,000 CAD. Of course, additional charges may apply for special or unforeseen options. The build time is estimated at 7 to 8 months.

But in the end, what you get is a truly original vehicle — a stunning replica of a legendary vintage car, delivered with modern flair!

L'Automobile Magazine

News

Business Directory

En

En  Fr

Fr